The aim and scope of the article

The article discusses the causes and circumstances that have conditioned the rapid spread of last century’s ideas about the new ways of combining art and science along with an in-depth review of how societies are influenced by such tendencies. In modern industries, atomization technology’s role is multifaceted primarily because of its versatility and adaptability. This also leads to a more detailed look at regions where the interrelation of art and society is most evident as well as how society influenced the economics and industry development. With further expansion of atomization technology, there will be balancers to various processes that control the spread of cutting-edge ideas and how they are utilized in industries. Further research in this area will undoubtedly yield new applications of the atomization technology in different industries.

Atomization Technologies Review

Pressure-Based Atomization

In most circumstances, pressure-based atomization is the most common way of atomization. This atomization employs the use of nozzle liquid propelled at high pressure. This method is mostly used in fuel injectors and is crucial engineering practice where there is a need for efficient and controlled combustion. Any fuel that is injected into the engine is usually atomized for better performance and less pollution.

Ultrasonic Atomization

Ultrasonic atomization works by emitting high-frequency bonds to convert liquid into mist. It may be advantageous in this case, where minimal kinetic energy is essential in finished products, for example, in perfume production and fine mist humidifiers. Unlike the pressure-based atomization method, ultrasonic atomization does not allow droplets to be formed randomly but rather more controlled, hence droplet size and distribution can be controlled depending on the situation.

Rotational Atomization

Rotational atomization is based on the use of a disc which spins rapidly, when the surface reaches a certain value, the liquid is flung out of the surface of the disc at extremely high speeds which enhances atomization due to centrifugal force. This method finds wide application in powder coating techniques and other processes where the particle size needs to be similar in size in food production processes. The rotating motion also helps particles to be uniformly around the coated surface.

Two-Fluid atomization: This technique disperses large volumes of liquid in the shape of droplets. It is common practice to do this in the process of spray drying. In two-fluid atomization, the droplet size can be varied to suit many different industrial hands.

Advancements in atomization technology and future perspectives: When thinking about the future, it is very crucial to note that the area of atomization technology is likely going to be enhanced by the integration of smart materials and digital control systems.Such advances aims to increase, precision and efficiency of the atomization processes thus increasing the number of possible applications. different ways of atomization that employed most of the resources required have an impact of the growth of environmental sustainability. The changing of atoms via dissolution, dispersion or even evaporation to make advanced and functionalized materials where the exact techniques needed were not categorize.

Ultrasonic Atomization

Ultrasonic atomization is a method that utilizes sound waves to disintegrate liquids into minute droplets. This technique is very useful in the medicine field where it helps in targeted drug applications. In the food sector, ultrasonic atomization is employed to produce very light textures and flavors which enhances the experience of food. This application is also used in the perfumery industry, where the distribution of smell requires a certain level of precision.

Electrostatic Atomization

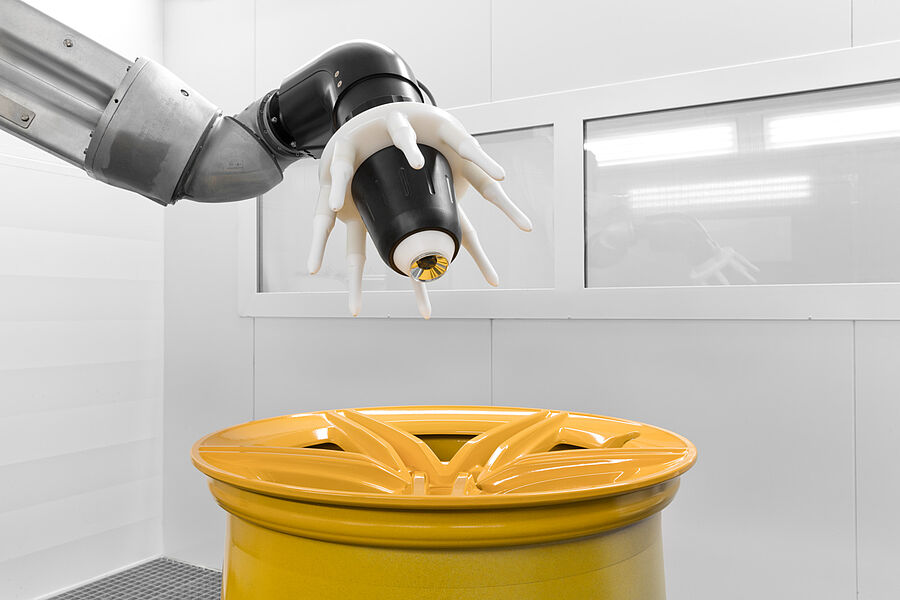

Electrostatic atomization makes use of electric charges to produce fine sprays. This technique is useful in automotive and electronics industry because it ensures a uniform spray coating. Electrostatic force allows each droplet to stick perfectly and uniformly which gives a high quality effect. New approaches are still being sought in regard to electrostatic atomization by upcoming technologies.

Advanced Applications of Atomization

Atomization also has an influence on new technologies and applications which are helping to modernise different areas of industries. For example, in the area of propulsion system development for space exploration, atomization technologies are being used to moscow atomization in the spacecraft engine which will increase the power and efficiency of the engines. In biotechnology, atomization is reported to provide the basis for overcoming the creation of microencapsulation technologies which is needed in drug delivery systems for targeted therapies and to reduce the side effects.

In addition, atomization is adding value to environmental technologies by helping to control and manage pollutants and airborne particulate matter. Atomization technologies guarantee environmental clean-up operations to be effective as well as practical. use of atomization in nanotechnology which is relatively new due to demand for synthesized and dispersed nanoparticles employed in electronics, coatings and medical devices. With the continuous progression in research, progress and indeed the state of atomization, the possibilities appear limitless which suggests a future where atomization will be significantly impact involution across numerous fields.

New and Emerging Atomization Types

In addition to or in expansion of the known ones, there are also emerging and experimental atomization which can be termed novelty. New methods that could span great distances from renewable energy to nanotechnology are being investigated by scientists. These experimental methods demonstrate the possibility of new applications and enhanced efficiency of existing systems being developed.

Atomization: Issues and Challenges

It is true that there has been a substantial development of atomization technologies, however, there are several issues that need to be addressed to fully utilize their power. First of all, one of the major issues is the amount of energy used in some of the atomization techniques. The emissions generated from processes such as pressure-based atomization or rotational atomization can be excessive and can increase the cost of carrying out the operations. With industries working towards saving the environment, there is a great opportunity to come up with ideas for the development of atomization processes that utilize less energy.

Another limitation is controlling the size of the droplets or particles produced in relation to the application. If there is a lack of control in particle size, as was the case with droplet formation, as in a primary atomizer, this would cause serious problems, especially in fields such as pharmaceuticals and food production where perfection is a must. The great concern that researchers have been having is about how to control atomization systems effectively for better results.

Most importantly, the operational cost, as well as maintenance cost of such atomization systems and devices, is quite expensive. Industries have to assess these costs to the operational benefits derived from advanced injection systems. One of the most crucial factors to be considered in the development of systems in the future for any industry is the maintenance of the system and the lifetime of the system as well.

The technology preferring other processes has also brought a number of problems for various industries. The efficient implementation of the new atomization techniques can be restrained by the integration with the existing systems and specialized knowledge. Nevertheless, gaps such as these may be tackled by synergetic actions within and across sectors, promoting the desired integration of processes with knowledge embedded in them. These included challenges can be overcome and as a result, the wide spectrum of atomization technology would be able to help to its potential in various new applications and greater operational efficiency.

Key Applications Across Industries

Medical and Healthcare

Precision of drug delivery is useful for healthcare. Atomization technology is revolutionized in drug manufacturing and vaccine distribution. Wherever inhalers and nebulizers are used means of atomization converts liquid medication into mists which doctors use in treatment of respiratory conditions. Such treatments have precise control and as a result, the patient’s effectiveness is increased, and adverse factors are decreased.

Manufacturing and Automotive

Atomization technology is also fundamental in the manufacturing processes of procedures such as paint spraying or coatings. Tuning the parameter of shape and smooth/ugly surfaces improves the quality of the product, enhances its life span. Similarly, the combustion of fuel in the atomization stage aids in the improvement of the performance of the engine and reduces the emission level.

Enhanced Product Quality

The product quality improvement is related to more effective atomization technology application. The consumers in manufacturing industries, healthcare or agriculture get high-quality end products. Consumer products are reliable and act on the consumers’ expectations every time they are used.

Environmental Advantages

Atomization technology is environmentally friendly as it addresses emission and waste reduction. In instances such as fuel injection and insecticide atomization/pesticide atomization, atomization technology minimizes the use of environmentally unsafe products. Hence, this technology helps make the world a safer and better place to live.

Pitfalls of the Atomization Method

Technical Pitfalls.

The atomization method, however, is not ideal for all applications as it does come with some technical flaws or challenges. Uniformity in the droplet size and the droplet size distribution is sometimes difficult to control, which reduces the effectiveness of the operation. However, engineers and scientists are continuously improving the methods to control these factors.

Industry Based Limitations

Taking atomization technology into use may be non-viable in certain industries due to high costs or scale limitations. For small witch businesses, atomization investment may be very tough for them. However, such an improvement of accessibility to atomization technique in business is expected in tighter competition area.

Environmental Impacts and Health Concerns

No doubt, atomization technology has environmental upshots. However, there are also risks associated with its use that need to be addressed. Certain materials used in atomization processes may be hazardous to health. Safe handling and disposal of materials remains important in order to minimize these risks.

Future Trends in Atomization Technology

Current Trends in the Advancement of Smart Atomization

Improved advances in atomization technology are now more dependent on new technological advances in AI. AI integration facilitates the management of processes by monitoring operating conditions and processing parameters continuously, thus improving efficiency. Advanced atomization facilitates more accurate and efficient processes.

Integration with IoT

Through IoT Japan can remotely monitor and control the entire atomization technology. The devices connected through IoT will gather vital data that will help determine when maintenance is due and how to effectively manage resources. Such enhancement improves operational performance as well as minimizes downtimes.

Sustainability and Eco-Friendly Materials

Sustainable development requirements are increasing the usage of green materials in atomization process. Studies are focusing on substances that are biodegradable in order to less affect the environment. This transformation comes in handy in the light of the ongoing global campaign for sustainable development.

Potential Applications in Emerging Sectors

Atomization technology is a walking encyclopedia in itself. It is only yet to be embraced fully in emerging sectors such as renewable energy and nanotechnology. There are many new interesting ideas which could change these industries for good. The sky is the limit in the pursuit of development.

Conclusion

The globalization of atomization technology has also contributed to innovation. Atomization technology is the only solution that can bring a competitive advantage to a business with its efficiency and ecosystem protection. Be it healthcare or agriculture, new avenues are being created with atomization and the quality of the products is being enhanced.

FAQs

Where can atomization technology be used?

In health care, it provides drug delivery solutions; in manufacturing, it applies coatings; in agriculture, it sprays pesticides, and in food and beverage, it infuses flavors.

What is the principle of ultrasonic atomization used in medicine?

With the help of sound waves, ultrasonic atomization generates tiny droplets that assist the patients in effective drug delivery via inhalers as well as nebulizers.

Why should one use atomization technology in today’s world?

The atomization method minimizes emissions and waste through controlled distribution, thereby supporting sustainable development in industries like manufacturing and agriculture.